CDMA Based modem

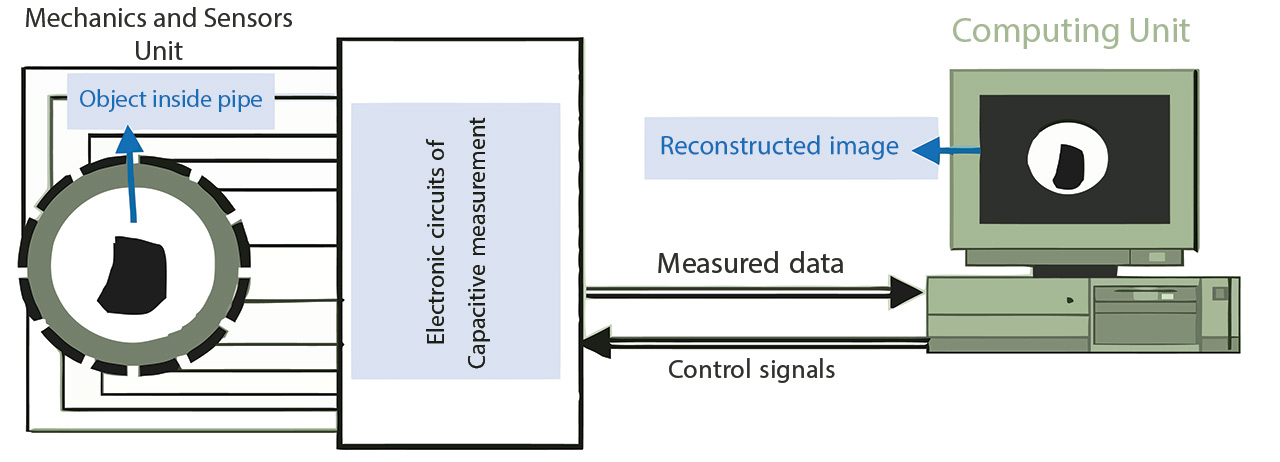

Implemented devices with capacitive tomography technology

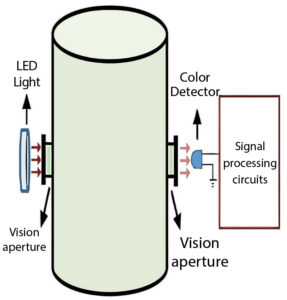

The general structure of the capacitive tomography system is shown in the figure above. In this system, capacitive electrodes are placed outside the tube containing the fluid and provide a non-destructive image of the tube’s cross-section and the objects or fluids passing through it. The following figure shows the fabricated laboratory sample. In this product, an external body (a smaller tube) is placed inside the main tube, and by applying electric fields to the electrodes and processing the resulting data, the cross-sectional image of the second tube is reconstructed on the computer. This image is highlighted in red.

Some facilities control the transportation of oil products through multiple pipelines. In the transportation process, different petroleum products are passed through these pipelines in sequential order. It is necessary to detect the time and manner of changing the received products on time in the reception facilities.

The laboratory product mix determination system can determine the type of passing product and the percentage of mixing of different petroleum products that have been created as a result of intermittent sending of petroleum products in a pipeline in an offline manner.

The color detection and control system can be used to control the product’s concentration intelligently or to detect the type of product passing through the tube. This system can distinguish the color of the product with an accuracy of 16 million modes.

The following figure illustrates the implemented sample.

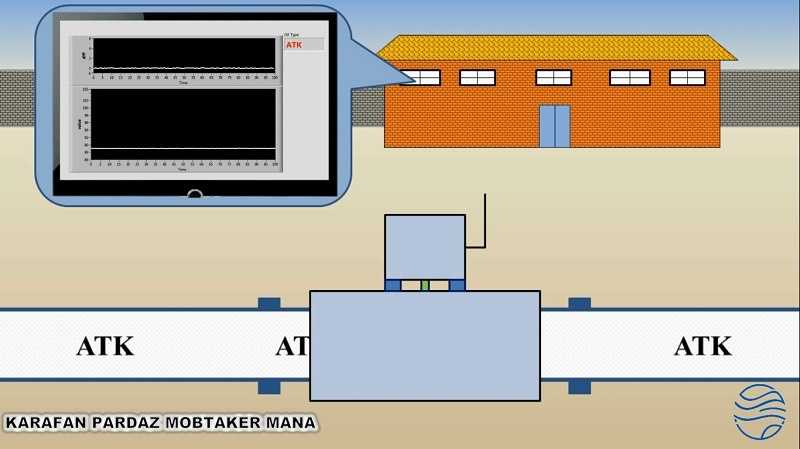

Interface detector system

In oil refineries, when petroleum products pass through pipes, operators face difficulty identifying the exact time of intersection and the type of petroleum products. Human resources must continuously extract manual petroleum samples to check the current passing product in the current procedure. The purpose of this invention is to detect the type of products passing through the pipelines automatically. In this video, you will get acquainted with the operation of this system.

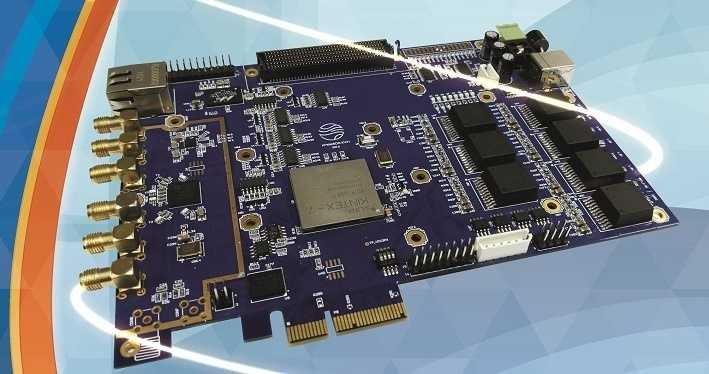

SDRP-K761 Board

Advanced hardware platform, suitable for implementing software radio (ALL IN One, SDR Board)

SDRP-K761 product, made by Karafan Pardaz Company, offers an advanced and powerful hardware platform. This product includes a powerful digital processor unit and a very high-quality analog mixer. The digital processor unit consists of a Xilinx Kintex7 chip with the ability to select XC7K160 / 325/410 models. The analog mixer unit using the AD9361 chip can also act as a full-sided tuner to cover the frequency range of 70MHz to 6GHz in a full-duplex manner. SDRP-K761 can be used in various systems such as transceivers, generating or receiving a variety of signals such as TV Broadcast, Cellular, Wi-Fi, FM, etc. This product has two input channels and two output channels.

Along with the hardware, HDL codes are prepared for the AD9361 section. With the help of these codes, all the settings of the AD9361 chip can be easily done without the need for a PC. It also has a 10/100/1000 Ethernet interface and PCIe-4lane and RS232 intermediates.

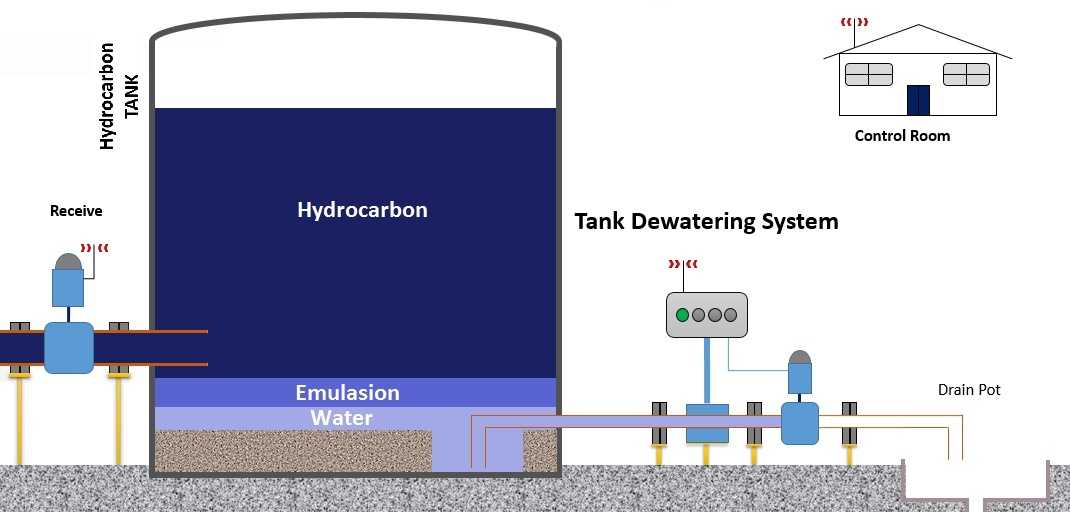

Tank dewatering System

In the oil, gas, and petrochemical industries, storage tanks are used to store crude oil and petroleum products. In most cases, a significant amount of water enters the tanks along with hydrocarbon materials and settles at the bottom of the tank due to its high density compared to hydrocarbon materials. Before transporting petroleum products to the next destination, the water collected at the bottom of the tanks must be drained and removed.

In most cases, the water draining operation is done manually by the operator. Draining water manually is a repetitive and time-consuming process, and the interface of water and oil materials is not easy to detect. This reason causes error and waste of a significant amount of valuable oil materials and in addition causes environmental pollution.

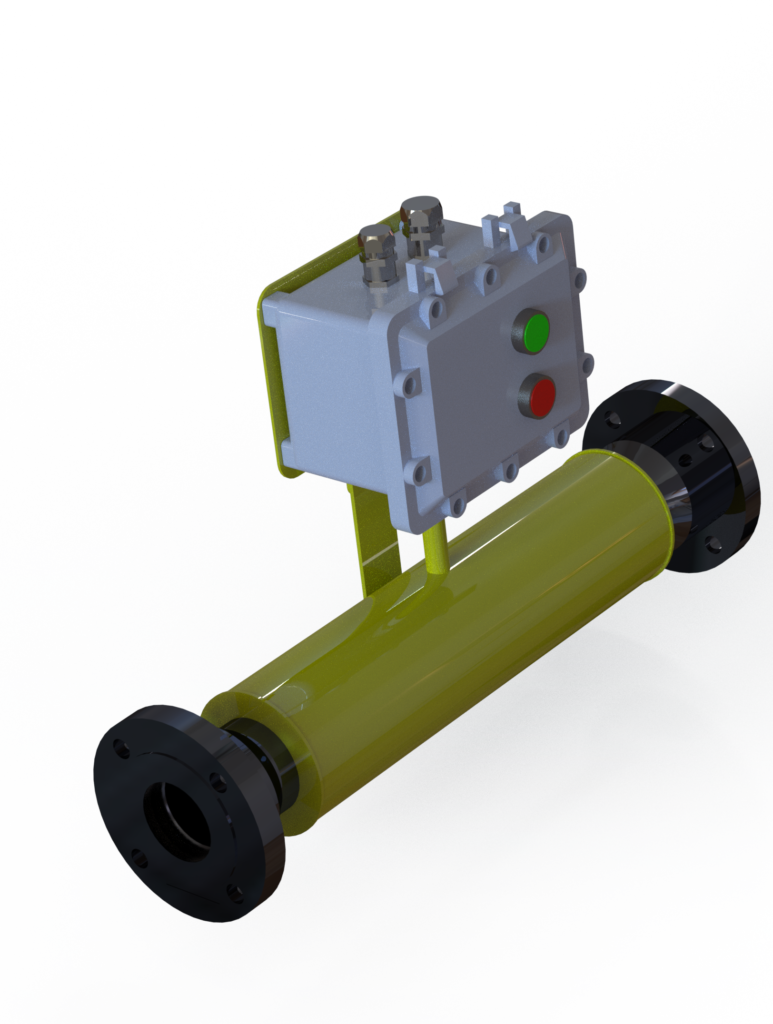

This device has completely solved this problem by automatically or semi-automatically draining the water of the tanks and causes the complete draining of the water without wasting the valuable materials inside the tank. One of the features of this device is the use of non -contact ECT sensors in its structure. And there is no physical contact between the sensors and the hydrocarbon passing through the pipe, and there is no obstacle in the discharge path. This prevents the sensors from corroding and increases their lifespan. This device has technical approval and Atex safety certificate.

Features and Benefits

✓Significant reduction in the wastage of crude oil and petroleum products when draining Tank’s water

✓ Reducing environmental, microbial and bacterial pollution

✓ Reducing the cost of wastewater Purification resulted from Tank’s Draining

✓ Increasing the storage capacity of tanks

✓ Reducing the amount of corrosion of equipment inside of tanks

✓ Long service life of the device due to non-contact sensors

✓ Easy installation without needing to empty the tank

✓ Perform safe (HSE) and accurate extraction

✓ Can be used standalone or through the control room

Application

This product can be used for draining water and

sludge from the bottom of tanks and Roof Draining in

the following industries:

✓ Oil and gas refineries

✓ Petrochemical industries

✓ Storage Tanks of Distribution network

✓ Export platforms and ships

✓ Fuel tanks of power plants

✓ Oil Extraction industry

The video below shows how this system works.