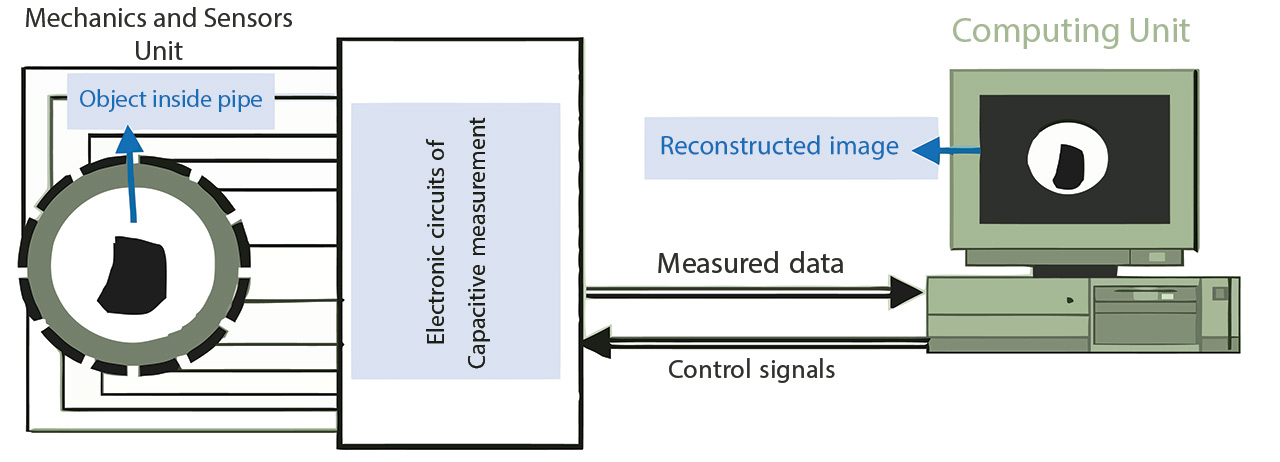

The general structure of the capacitive tomography system is shown in the figure above. In this system, capacitive electrodes are placed outside the tube containing the fluid and provide a non-destructive image of the tube’s cross-section and the objects or fluids passing through it. The following figure shows the fabricated laboratory sample. In this product, an external body (a smaller tube) is placed inside the main tube, and by applying electric fields to the electrodes and processing the resulting data, the cross-sectional image of the second tube is reconstructed on the computer. This image is highlighted in red.

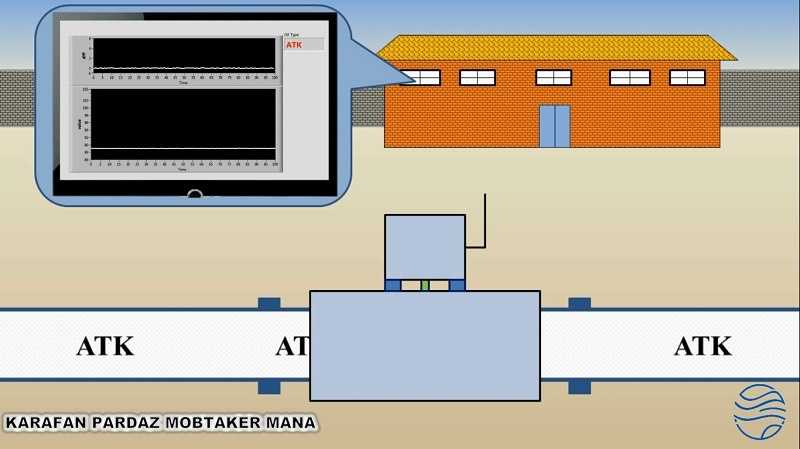

Some facilities control the transportation of oil products through multiple pipelines. In the transportation process, different petroleum products are passed through these pipelines in sequential order. It is necessary to detect the time and manner of changing the received products on time in the reception facilities.

The laboratory product mix determination system can determine the type of passing product and the percentage of mixing of different petroleum products that have been created as a result of intermittent sending of petroleum products in a pipeline in an offline manner.

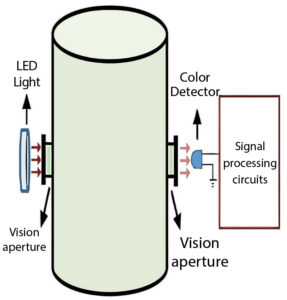

The color detection and control system can be used to control the product’s concentration intelligently or to detect the type of product passing through the tube. This system can distinguish the color of the product with an accuracy of 16 million modes.

The following figure illustrates the implemented sample.